Many of the embedded devices in the market need to go through lengthy hardware and software verification cycles. This process is time consuming and needs extra care to deliver defect free product. Since manual testing is an error prone and time consuming activity, we cannot completely rely on it. It is unreliable for delivering defect free products in the estimated time. It is particularly crucial and time critical when there are large number of devices for production.

Automated testing can help us achieve this goal. Automated testing tools save time and money of the vendor to deliver quality product on time.

Various automated tools are available in the market; but most of them are domain specific and cannot be customized. Aftek's TestJig is a handy tool. It provides a customized solution to reliably automate the complete testing cycle.

TestJig provides a solution to test embedded circuit boards and the software on the boards. This solution can be used for all types of testing including functional testing, regression testing and load testing.

Hardware testing mainly deals with the testing for production. It involves the testing of hardware interfaces for production go / no-go. It also includes the testing of the end product with software running on it. TestJig is useful for both production go / no-go testing and end product testing.

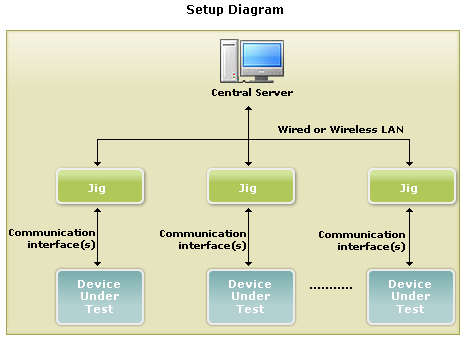

Using the TestJig solution, multiple boards can be tested simultaneously, it saves considerable verification time. See the illustration below. The Device Under Test (DUT) is connected to the Jig board through various interfaces. These Jig boards are controlled from the central server connected via wired or wireless LAN.